| Cue Type | Break |

|---|---|

| Construction | Full laminated hard rock maple core |

| Handle | Victorian Mountain Ash |

| Forearm | Magogany |

| Butt Sleeve | Tomahawk |

| Butt Collar | Tomahawk |

| Joint Collar | Full laminated hard rock maple core |

| Butt Cap | Tomahawk |

| Rings | Black Acrylic/Brass |

| Pin | Uniloc Quick Release |

| Shaft | Rock maple with carbon fiber core |

| Ferrule | Juma capped |

| Tip | Samsara |

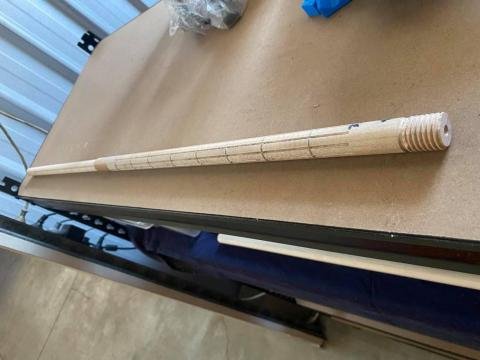

I have always wanted to take a shot at making a cue, and this was my first. It is a break cue.

The timber for the butt core and the shaft were imported, while I used locally sourced timbers for the handle and forearm.

Handle is Mallee burl, and the forearm is Mahogony. These were glued to the core with West System epoxy.

Butt sleeve and joint collars are made of Tomahawk. I added some brass rings to dress it up.

Ferrule is capped Juma.

Pin is Uni-loc quick release.